Boost sales, reduce waste

Your on-demand design and print solution -accessible anytime, anywhere.

Through easy-to-use technology and integrated smart design, hyble helps you to create high impact, customisable point of sale materials whilst maintaining brand integrity and reducing costs.

Created together with the world’s leading drinks brands

Create better content, faster

Design high-quality point of sale materials with simple creation tools, customisable templates and automated text.

Work together with your customers and team, to create stunning designs, get approvals and print directly from the platform.

Collaborate more

Protect your brand

Manage your brand assets, maintain consistency and help your reps stay on brand with every new design.

Stop waste

Print on-demand via our vetted network of cloud printers, choose from a range of sustainably sourced and recyclable paper for better environmental impact.

hyble empowers sales reps to unlock their creativity and create beautiful content across menu, point of sale material and social media. No design experience needed.

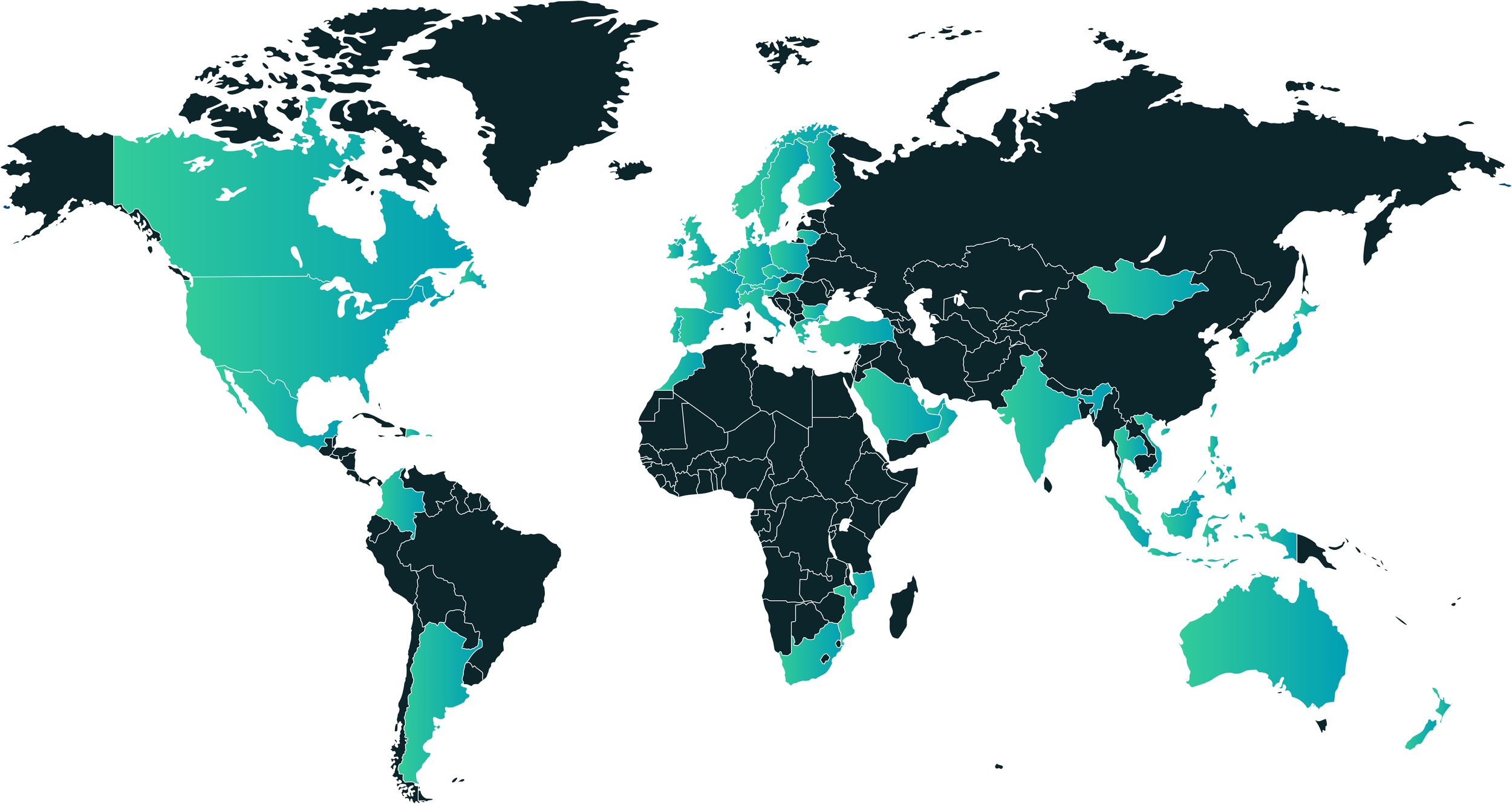

Now operating in over 50+ countries globally, we are the fastest way to boost revenue and efficiency whilst maintaining brand integrity.